Firefighter Proving Grounds

Engine Company Operations : Solving problems by addressing the basics

Engine Company Operations: Solving problems by addressing the basics

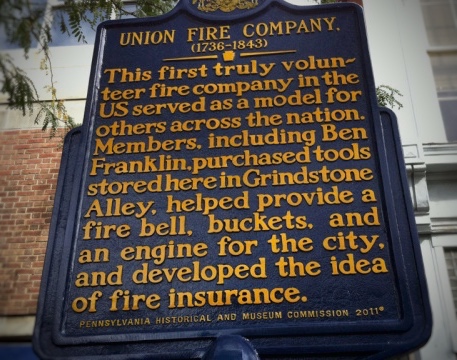

Benjamin Franklin's first organized volunteer fire department in Philadelphia in 1736 had many commonalities to our fire service today, with one underlying component that may be the most important factor - water delivery. Many things have changed since the first fire department, but the vital component of water delivery may be one thing that has changed the least. Water delivery to the fire area is the heart of the fire service and we must perfect every aspect of it.

Benjamin Franklin's first organized volunteer fire department in Philadelphia in 1736 had many commonalities to our fire service today, with one underlying component that may be the most important factor - water delivery. Many things have changed since the first fire department, but the vital component of water delivery may be one thing that has changed the least. Water delivery to the fire area is the heart of the fire service and we must perfect every aspect of it.

NIOSH reports on line of duty deaths are filled with investigations, interviews, and recommendations. Far too often the “contributing factors” section is filled with phrases such as “failure to deploy hose line,” “inadequate water supply,” “engine tactics,” “line coordination,” or “delay in getting water.”

Why do we continue to see this? Why is water application such a common difficulty? What are we doing wrong, and how do we make sure we are getting water to the seat of the fire?

In these next few posts we will be discussing how we can help prevent some of these ongoing problems. We are not recreating the wheel. We are all here to do what the fire service does best: pass on the information we have been taught to our peers and the next generation. We will focus on engine company basics and our mission: water delivery, application, and extinguishment.

Preparing for the response

It has been said that the size-up starts at the receipt of the alarm. We believe otherwise. Size-up is an ongoing process as you go on your “nuisance” runs - alarms, bells, smells, and EMS responses. For volunteer firefighters, you have the advantage of living where you work and being familiar with layouts, occupancy types, storage/clutter conditions, and hydrant locations. We know the types of buildings we are responding to and how our water supply is delivered.

Are we located in an urban setting with fire hydrants every few hundred feet?

Do we live in a rural area where we need to draft or relay water via tankers? Or, perhaps we have a mix of both.

Identifying our water source is vital so we can prepare our hose beds. Hose beds in your department should be uniform for ease of use by any member, but must also be tailored to your community’s needs (building types, topography, and hydrant locations).

What are your department’s guidelines on stretching? Are we prepared to backstretch (fire to hydrant), estimating and controlling a stretch of a dead bed or static bed? Is it procedure to in-line stretch (hydrant to fire) securing a water source and stretching supply line to the vicinity of the fire building? Some apparatus may be set up to stretch a multitude of ways. If this is the case, do we know when and how to deploy each?

The Backstretch ( Fire to Hydrant): With this system, the first arriving engine apparatus stops in the front of the fire building. With the backstep in line, or just past the entrance, the hand stretch will begin. Firefighters estimate the amount of hose needed to reach the fire. Generally, pre-connected attack lines are not used when performing a back stretch. The hose will come from the back step, either from a static or dead bed. The nozzle firefighter takes a sufficient amount of hose, either one or two lengths (this will be discussed in a later post) then takes a few steps and stops. Next the back-up firefighter will take their folds. If staffing provides for more firefighters beyond this point, they would do the same. If not, the last firefighter will estimate and remove the remaining amount of hose needed for the stretch to reach the main body of fire and lay it along the curb line or on the sidewalk if possible. It's important not to place it in the street. This will delay and or impede positioning of later arriving aerial apparatus. Once enough hose is in the street the nozzle firefighter can advance through the building as the engine chauffeur is signaled to proceed to the hydrant. This allows the apparatus to stretch the remaining hose. Upon arrival at the hydrant, the chauffeur can now test and hook up the supply line. In an instance where a time consuming stretch is anticipated i.e. upper floors, or long hallways, the chauffeur can also break the line or control the stretch himself and connect to a discharge.

The Backstretch ( Fire to Hydrant): With this system, the first arriving engine apparatus stops in the front of the fire building. With the backstep in line, or just past the entrance, the hand stretch will begin. Firefighters estimate the amount of hose needed to reach the fire. Generally, pre-connected attack lines are not used when performing a back stretch. The hose will come from the back step, either from a static or dead bed. The nozzle firefighter takes a sufficient amount of hose, either one or two lengths (this will be discussed in a later post) then takes a few steps and stops. Next the back-up firefighter will take their folds. If staffing provides for more firefighters beyond this point, they would do the same. If not, the last firefighter will estimate and remove the remaining amount of hose needed for the stretch to reach the main body of fire and lay it along the curb line or on the sidewalk if possible. It's important not to place it in the street. This will delay and or impede positioning of later arriving aerial apparatus. Once enough hose is in the street the nozzle firefighter can advance through the building as the engine chauffeur is signaled to proceed to the hydrant. This allows the apparatus to stretch the remaining hose. Upon arrival at the hydrant, the chauffeur can now test and hook up the supply line. In an instance where a time consuming stretch is anticipated i.e. upper floors, or long hallways, the chauffeur can also break the line or control the stretch himself and connect to a discharge.

Experience has shown that doing this prior to completing the hook up of a supply line allows for the chauffeur to give tank water at the moment it is called for. Then he can concentrate the efforts of getting a supply line connected to the water source. **If implemented in this order the chauffeur MUST ENSURE ALL OPERATING UNITS ARE AWARE THE ATTACK LINE IS ON TANK WATER ONLY. Once hydrant water is introduced, a like communication must take place. In a time where the fire service is strapped for manpower, whether it's recruitment and retention on the volunteer side or battling city hall for sufficient staffing on the career side, significant consideration must be taken on how we are prepared to quickly deploy our initial attack lines. Using the backstretch takes the least amount of personnel and with regular practice can be successfully implemented thus getting water to the seat of the fire quickly.

With this system, a minimum of three firefighters can stretch, flake out, chase kinks, and possibly begin the initial attack. Members on the stretch, with the exception of the nozzle position, must remember to be fluid throughout the operation. These members must continue to move up and down the line to ensure butts don’t get caught on tires, under doors, banisters, stairs, or any other obstructions in the path of the line. The nozzle firefighter does not need anyone to “back them up” while stretching or flaking out the line.

The back stretch is a great option when manpower is short if hydrant distances are not extreme and the hose beds are prepared accordingly. Stretching in this fashion also allows for the front of the building to be left open for later arriving aerial apparatus, whether it be first or second due or FAST/RIT.

When you subscribe to the blog, we will send you an e-mail when there are new updates on the site so you wouldn't miss them.

Comments 1

IN Philadelphia , either 3 or 4 length 1 3/4" pre connects are used and pulled in a backstretch from either side of our bed. 2 story 3 lengths 3 story 4 lengths. The driver drops the tank and then proceeds to find a supplemental water source.